For over a century, X-ray crystallography has been the gold standard for determining the structure of crystalline materials. This technique excels when analyzing intact crystals, but many materials exist only in powdered form, composed of randomly oriented crystal fragments. This presents a significant challenge in reconstructing the complete structure.

“Structure is the fundamental building block of understanding any material,” emphasizes Danna Freedman, the Frederick George Keyes Professor of Chemistry at MIT. “It’s crucial for superconductivity, magnets, photovoltaics – any materials-centric application you can imagine.”

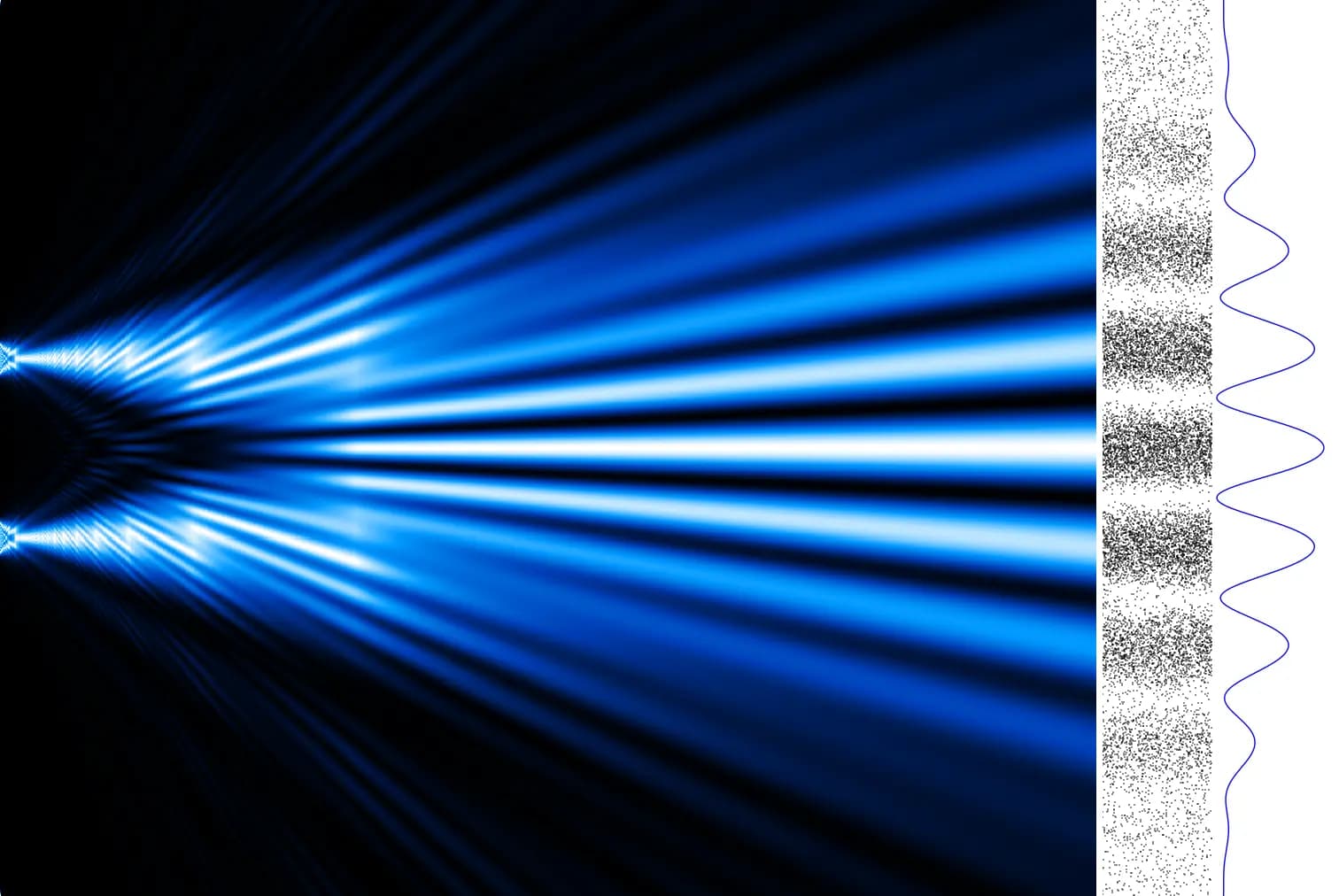

Crystalline materials, encompassing metals, and most inorganic solids, are formed by repeating units arranged in a lattice. These units, akin to “boxes” with specific shapes and sizes, contain precisely positioned atoms. X-rays diffracted by these lattices provide insights into atomic positions and bonds. However, deciphering structures from powdered crystals, where fragments lack the full 3D information, becomes significantly more complex.

Freedman and her team tackled this challenge by developing Crystalyze, a machine-learning model trained on a vast dataset of over 150,000 materials from the Materials Project database. They first used an existing model to simulate X-ray diffraction patterns for these materials, then trained Crystalyze to predict structures based on these patterns.

Crystalyze breaks down structure prediction into subtasks: determining the lattice “box” size and shape, identifying constituent atoms, and predicting their arrangement. For each diffraction pattern, the model generates multiple possible structures, which are then validated against predicted diffraction patterns.

“Our model is generative, meaning it can create structures it hasn’t encountered before,” explains Eric Riesel, an MIT graduate student and lead author of the study published in the Journal of the American Chemical Society. “This allows us to generate numerous guesses and predict their corresponding powder patterns. A match between input and output confirms our success.”

The team rigorously tested Crystalyze on thousands of simulated and experimental diffraction patterns, achieving an accuracy rate of 67% on previously unseen data. Impressively, the model successfully determined structures for over 100 previously unsolved patterns from the Powder Diffraction File.

Furthermore, Crystalyze played a crucial role in discovering structures for three novel materials synthesized in Freedman’s lab. These materials, formed by forcing unreactive elements to combine under high pressure, exhibit unique crystal structures and properties.

The ability to determine powdered crystal structures has far-reaching implications for materials science. Recognizing its broad applicability, the MIT team has made Crystalyze accessible through a web interface at crystalyze.org. This groundbreaking tool promises to accelerate materials discovery and innovation across diverse fields.

Responses (0 )