Titanium alloys are the backbone of numerous industries, from the soaring heights of aerospace engineering to the intricate world of biomedical devices. Their strength, corrosion resistance, and impressive strength-to-weight ratio make them indispensable. However, the pursuit of enhanced strength in these alloys often comes at the cost of ductility, limiting their applications. Now, a team of researchers at MIT, working in tandem with ATI Specialty Materials, has unveiled a groundbreaking approach to transcend this limitation. Their findings, published in the journal Advanced Materials, detail a method for crafting titanium alloys that possess an unprecedented blend of strength and ductility, potentially unlocking a new era of material applications.

Professor C. Cem Tasan, the POSCO Professor of Materials Science and Engineering and an associate professor of metallurgy, highlights the versatility of titanium alloys: “Through careful selection of the alloying elements and their relative proportions, and of the way the material is processed, you can create various different structures, and this creates a big playground for you to get good property combinations, both for cryogenic and elevated temperatures.”

The team’s breakthrough hinges on a multi-scale approach, meticulously tailoring the alloy’s chemical composition, lattice structure, and processing techniques. They discovered that by carefully selecting alloying elements, they could optimize the crystal structure of the alpha phase, one of the two intermixed phases present in some titanium alloys. This optimization, in turn, facilitates specific deformation mechanisms, enhancing the alloy’s overall ductility.

Furthermore, the researchers found that a processing technique known as cross-rolling played a pivotal role in achieving the desired combination of strength and ductility. This technique, when applied with the optimized alloy composition, resulted in a unique microstructure where the alpha and beta phases shared deformation uniformly. This harmonious deformation, as Tasan describes it, effectively mitigates the risk of cracking that often plagues alloys with disparate phase responses to stress.

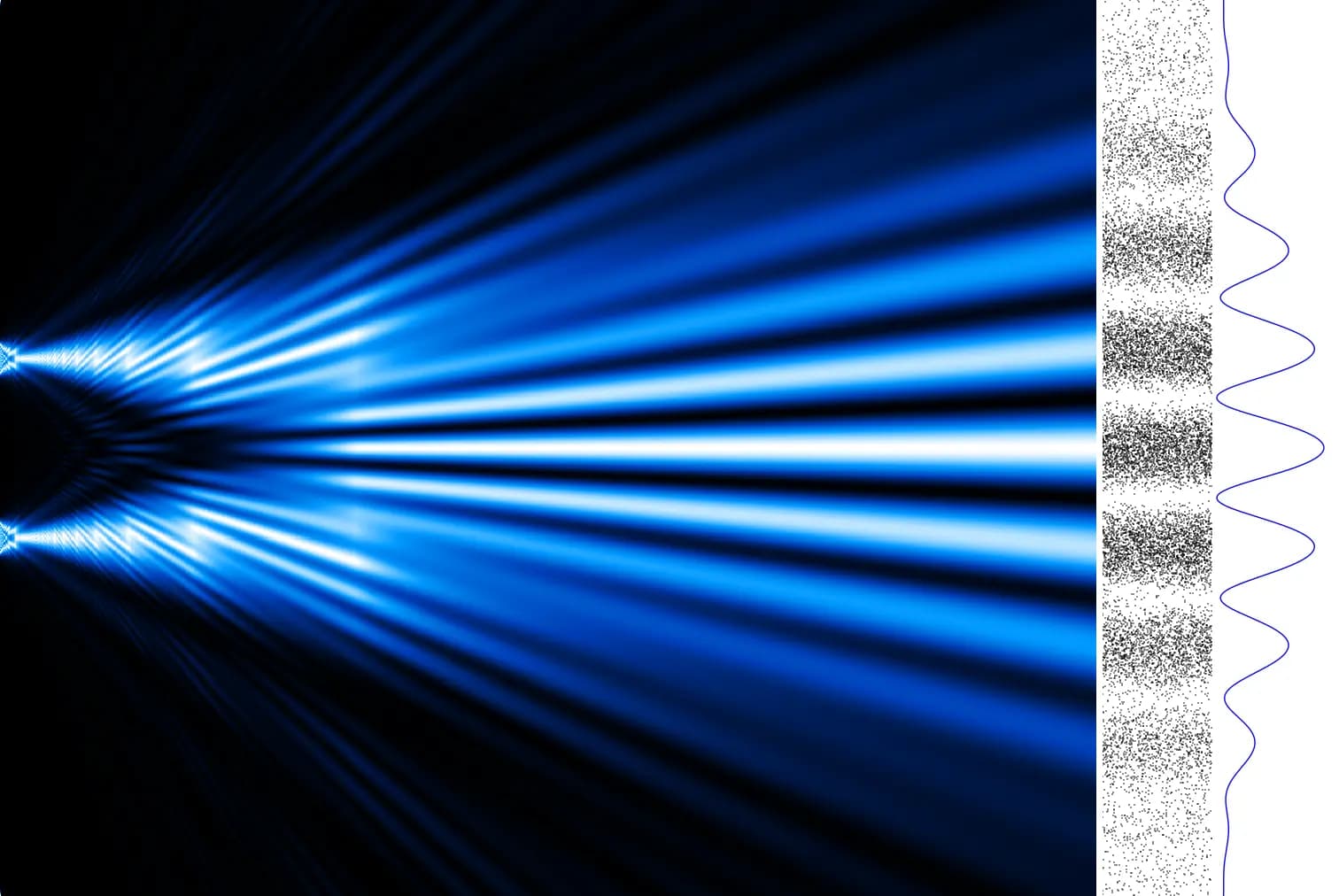

To unravel the mechanisms at play, the team subjected various alloys to rigorous testing under a scanning electron microscope. This allowed them to observe in realtime how the alloys’ microstructures responded to mechanical stress. Through these observations and detailed chemical analyses, they pinpointed the precise parameters—composition, proportions, and processing methods—that yielded the most desirable properties.

The results speak for themselves. Tasan confidently states, “When we look at the overall properties” of the titanium alloys produced using their system, “the properties are really much better than comparable alloys.” This research, driven by industrial collaboration, has not only yielded a commercially viable production method but has also deepened our fundamental understanding of crystal plasticity.

The potential applications of these findings are far-reaching. Tasan envisions their impact on “any aerospace application where an improved combination of strength and ductility are useful,” adding that this discovery “is providing new opportunities.” The research, supported by ATI Specialty Rolled Products, has leveraged the cutting-edge facilities of MIT.nano and the Center for Nanoscale Systems at Harvard University, underscoring the power of collaborative innovation in advancing materials science.

Responses (0 )