The scorching surface of Venus, where temperatures can climb to 480 degrees Celsius (hot enough to melt lead), is an inhospitable place for humans and machines alike. One reason scientists have not yet been able to send a rover to the planet’s surface is that silicon-based electronics can’t operate in such extreme temperatures for an extended period.

For high-temperature applications like Venus exploration, researchers have recently turned to gallium nitride, a unique material that can withstand temperatures of 500 degrees or more. The material is already used in some terrestrial electronics, like phone chargers and cell phone towers, but scientists don’t have a good grasp of how gallium nitride devices would behave at temperatures beyond 300 degrees, which is the operational limit of conventional silicon electronics.

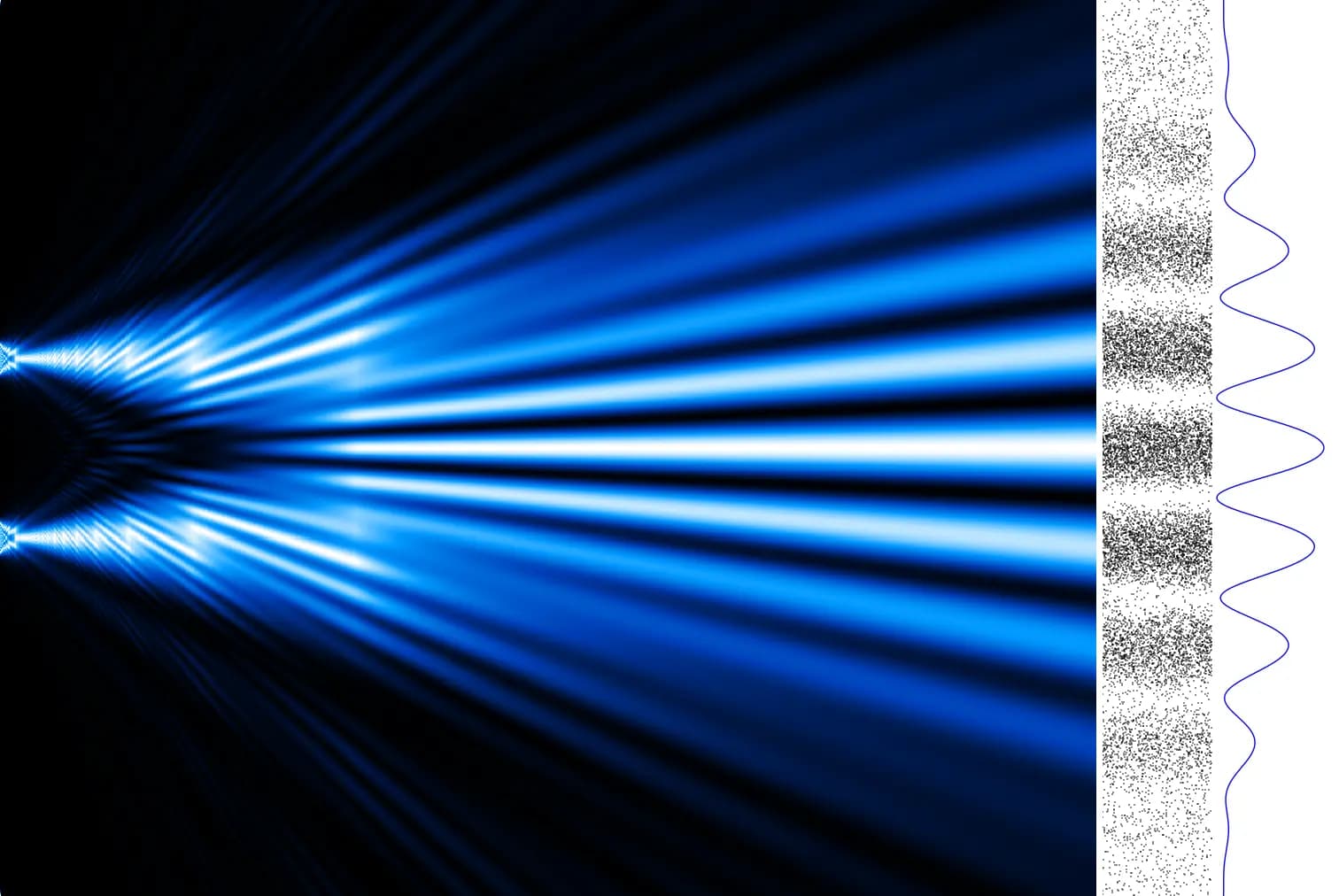

In a new paper published in Applied Physics Letters, which is part of a multiyear research effort, a team of scientists from MIT and elsewhere sought to answer key questions about the material’s properties and performance at extremely high temperatures. They studied the impact of temperature on the ohmic contacts in a gallium nitride device. Ohmic contacts are key components that connect a semiconductor device with the outside world.

The researchers found that extreme temperatures didn’t cause significant degradation to the gallium nitride material or contacts. They were surprised to see that the contacts remained structurally intact even when held at 500 degrees Celsius for 48 hours.

We went in thinking the contacts or the gallium nitride material itself would degrade significantly, but we found the opposite. Contacts made with both methods seemed to be remarkably stable

,” says John Niroula, an electrical engineering and computer science (EECS) graduate student and lead author of the paper.

Understanding how contacts perform at extreme temperatures is an important step toward the group’s next goal of developing high-performance transistors that could operate on the surface of Venus. Such transistors could also be used on Earth in electronics for applications like extracting geothermal energy or monitoring the inside of jet engines.

“Transistors are the heart of most modern electronics, but we didn’t want to jump straight to making a gallium nitride transistor because so much could go wrong. We first wanted to make sure the material and contacts could survive, and figure out how much they change as you increase the temperature. We’ll design our transistor from these basic material building blocks,” says Niroula.

While gallium nitride has recently attracted much attention, the material is still decades behind silicon when it comes to scientists’ understanding of how its properties change under different conditions. One such property is resistance, the flow of electrical current through a material.

“Especially when you go to smaller dimensions, a device’s performance often ends up being limited by contact resistance. People have a relatively good understanding of contact resistance at room temperature, but no one has really studied what happens when you go all the way up to 500 degrees,” Niroula says.

Moving forward, the researchers plan to use what they learned in these experiments to develop high-temperature gallium nitride transistors. “In our group, we focus on innovative, device-level research to advance the frontiers of microelectronics, while adopting a systematic approach across the hierarchy, from the material level to the circuit level. Here, we have gone all the way down to the material level to understand things in depth. In other words, we have translated device-level advancements to circuit-level impact for high-temperature electronics, through design, modeling and complex fabrication. We are also immensely fortunate to have forged close partnerships with our longtime collaborators in this journey,” says Qingyun Xie, a co-author of the paper.

This work was funded, in part, by the U.S. Air Force Office of Scientific Research, Lockheed Martin Corporation, the Semiconductor Research Corporation through the U.S. Defense Advanced Research Projects Agency, the U.S. Department of Energy, Intel Corporation, and the Bangladesh University of Engineering and Technology. Fabrication and microscopy were conducted at MIT.nano, the Semiconductor Epitaxy and Analysis Laboratory at Ohio State University, the Center for Advanced Materials Characterization at the University of Oregon, and the Technology Innovation Institute of the United Arab Emirates.

Responses (0 )